Picking the right excavator bucket size can make or break your project. A bucket that's too small slows you down, while one that's too big risks damaging your machine. You need a size that matches your equipment and material. This choice boosts effic...

VIEW MORE

Excavator buckets rely on high-strength materials to handle demanding tasks. You’ll find that the main materials, such as alloy steel and AR steel, offer exceptional durability. These materials resist wear and maintain toughness under pressure....

VIEW MORE

A pulley system helps you lift or move heavy objects with less effort. Its primary function is to change the direction of the force you apply. By doing this, it redistributes the force and makes tasks easier. You can use it to handle loads that would...

VIEW MORE

The size and capacity of drilling equipment play a crucial role in determining its effectiveness for specific tasks. You need to select equipment that matches the demands of your project to ensure smooth operations. Using tools that are too small or ...

VIEW MORE

Drilling equipment plays a vital role in ensuring smooth and efficient operations. When you address common issues promptly, you enhance safety and reduce costly delays. Ignoring these problems can lead to serious risks, including operational breakdow...

VIEW MORE

Technology advanced modern drilling equipment in ways that have reshaped industries. You now benefit from tools that work faster, safer, and with greater precision. These innovations reduce errors and improve outcomes. Drilling systems today use cutt...

VIEW MORE

Investing in drilling equipment demands careful evaluation of various costs to ensure a sound financial decision. You must consider both tangible and intangible expenses that directly impact your budget and operations. Tangible costs include the phys...

VIEW MORE

Choosing the right drilling equipment for your site is essential. The geological conditions of your location directly impact the success of your operations. Using the wrong tools can lead to inefficiency, equipment damage, or even safety hazards. A p...

VIEW MORE

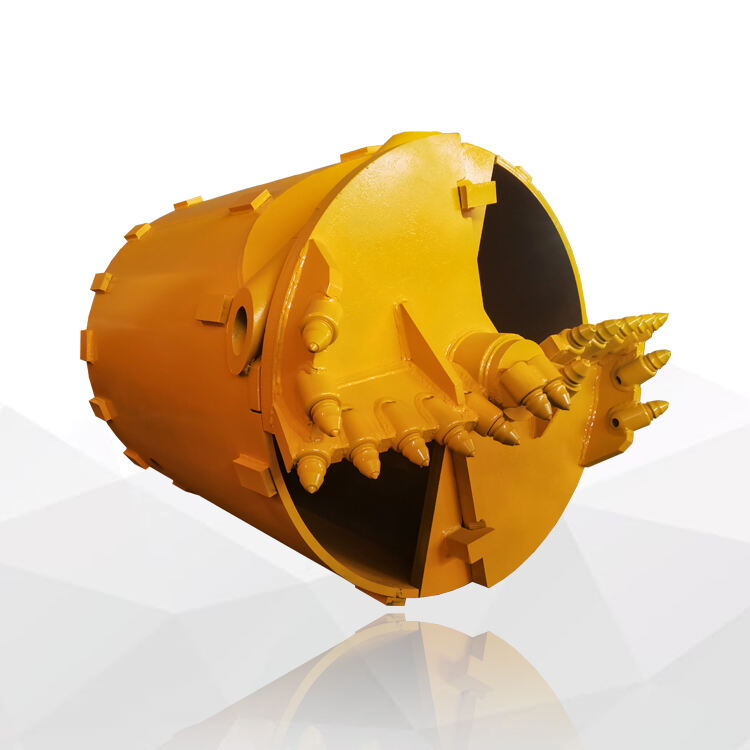

Introduction The drill bucket we choose for a job is one of the most important aspects affecting the rate at which a rotary drilling rig can work. There are different types of drill buckets for various geological conditions. Understanding which of th...

VIEW MORE

Introduction The first and foremost decision to make when planning rotary drilling works is the selection of the appropriate drill bucket. That means they need to be felt by the condition in the geological, since that is what we designed and built th...

VIEW MORE

Introduction To the uninitiated, a rotary drilling hole full of mud may look odd – this is actually an interstitial and essential part of the drilling process. Whatever helps drill in an accurate and efficient manner is called mud in rotary dri...

VIEW MORE

Introduction Rotational drilling cutter in addition to cast-in-situ heap technology is just a course of action by which no field are dubious as it really is efficacy and reliable efficiency can make it considered one of the integral approach that mos...

VIEW MORECopyright © 2025 Quanzhou Xinfenghua Machinery Development Co., Ltd. All rights reserved. — Privacy Policy