Introduction

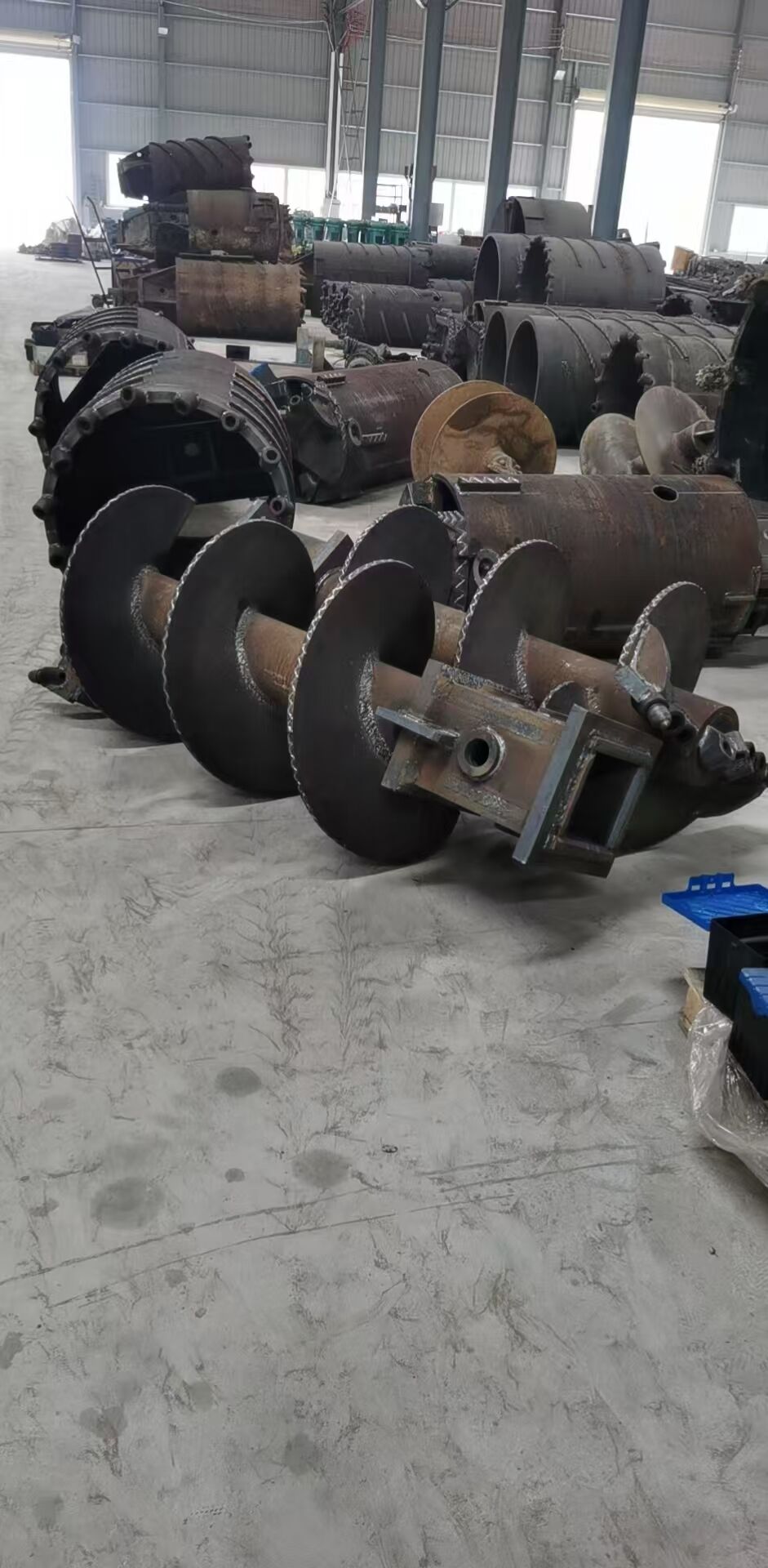

A borehole drilling machine is a device used to drill the ground for core samples, or other sample monitoring devices, so that it can be accessed from anywhere in the world. But these machines can be extremely dangerous as well, if they are not used properly. In this article, we will explain the safety measures for the borehole drilling machine to make sure that the operator stays in a safe working condition and keeps applying all essentials.

Training and Qualification of Operators

Training is the key to preventing accidents. And an operator needs to be trained thoroughly with the machine operations, safety features and operational limitations. The specifics of certification and qualification is subject to regional or industry requirements, however all operators should be certified. It is as well important that one gets familiar with the operation manual, from which you will learn how to operate and safety drill with the drilling machine.

PPE — Personal Protective Equipment

Anyone using a borehole drilling machine MUST use PPE. Helmets, safety glasses; ear protection to protect against falling debris, dust and flying particles. Gloves and safety boots with steel toes offer extra protection from cut or puncture injuries as well as crush hazards. The correct use of PPE and looking after PPE and having it checked regularly is also very important in preventing injury.

Preparation and Evaluation Site

A thorough pre-assessment of the drill site needs to be conducted before drilling operations can commence. Unstable footing, rough terrain and overhead risk are the common things that may lead to critical accidents. The area must be free from impediment and sufficiently space for secure usage. Safety zone and warning sign helps to prevent unauthorized entry in works area.

Inspection and Repair of the Machine

Before use, it is necessary to make a pre-operational inspection on the drilling machine to reveal any safety issues. During this inspection signs of wear, damage or loose components will be checked for. By having a planned maintenance schedule in place, the machine is less likely to go wrong making it safer. Maintained In Accordance With Manufacturer's Instructions By A Qualified Personnel.

Safe Operating Procedures

Borehole Drilling Machine safety operation procedures Users also need to turn on and off the machine as instructed by the manufacturer, handle drilling rods or bits with care, and drill at suitable speed and pressure. This can cause accidents or equipment breakdowns through failure.

Treatment and Disposition of Drilling Fluids

Improperly handling drilling fluids (muds & chemicals) can expose workers to many hazards. Operators should use the proper personal protective equipment (PPE) when handling these materials so as not to spill them and inhale or be exposed. On the other hand, adequate hazardous materials storage and proper disposal are key to protect both a workforce laboring in that environment and the environment itself.

Emergency Procedures

Drilling emergency response plans should be established. Operators should know the first aid kit and where to find a fire extinguisher, as well as be trained in their operation. Evacuation routes and assembly points should be clearly identified and reviewed with the team frequently.

Electrical Safety

Most borehole drilling machines are dependent on direct or alternating current (DC/AC), which can cause undue hazards if not properly managed. Operators must provide and maintain connections to any electric power needed for fire equipment, and such wiring should be properly protected from exposure to water sources. Cables that show the slightest bit of wear should be replaced immediately. GFCIs: GFCIs are an extra level of protection against electric shock.

Noise and Vibration Control

Hearing loss and adverse health effects can result from long-term exposure to noise and vibration. Operators should only use noise cancelling equipment and anti-vibration mounts wherever possible. It also proposes periodic hearing checks for operators to check and prevent the possibility of hearing damage.

Working with Others

This is key in being able to communicate with your team during drilling operations. And clear roles and responsibilities go a long way in ensuring that there are no misunderstandings, or fender benders for that matter… Proper rigging and lifting protocols are required for the transport of more considerable equipment in order to prevent injury.

Post-Operational Procedures

Safety Measures After its use, making sure the drilling machine is safely keep accommodate obstacle is very significant. Abandon and prevent any roll off when the machine becomes re-locked State of all controls, bid switch on! Cleaning and straightening up are practices followed post-operational procedures to ensure a safe and systematic work environment.

Regulatory Compliance

Regardless of where drilling occurs, it is essential that locals know and implement their state's safety rules. Operators must also record their activity in accordance with environmental regulations and maintain records for health and safety inspections, as well as audits.

Conclusion

Not only for the staff but also, in order to conserve that it's extremely important to take safety measures even prior when you run a borehole drilling equipment. If operators follow the guidelines we have discussed in this article they will be able to reduce risks and run efficient and effective drilling operations. Risk policies led with proactive safety culture, underlined with committed training in the field and proper equipment are the great wheel to turn for successful drilling work.

Table of Contents

- Introduction

- Training and Qualification of Operators

- PPE — Personal Protective Equipment

- Preparation and Evaluation Site

- Inspection and Repair of the Machine

- Safe Operating Procedures

- Treatment and Disposition of Drilling Fluids

- Emergency Procedures

- Electrical Safety

- Noise and Vibration Control

- Working with Others

- Post-Operational Procedures

- Regulatory Compliance

- Conclusion