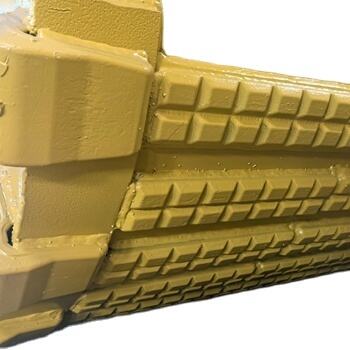

Versatile Attachment for Multiple Tasks

With a Bobcat excavating machine, you can go everywhere, do anything and tackle anything! Whether it's digging, grading or breaking through the toughest materials, these teeth can do all the work. Since the same teeth can perform a wide range of activities, you don't have to pay for multiple attachments. Profits for the end-user's wallet. With today's more exacting customers, with the new Bobcat price policy and machinery quality you can always meet their needs quickly. Deflection of the wings produces lift and steering. Thus an aircraft can be manoeuvred in almost any direction.